When it comes to electrical installations, small components often make the biggest difference in ensuring safety, functionality, and longevity. One such often-overlooked yet critical component is the multi-hole cable gland. Whether you’re wiring up a residential space, a commercial facility, or an industrial plant, the right cable gland can make all the difference in ensuring a secure, organized, and safe electrical setup. But with so many options available, how do you know which multi-hole cable gland is the perfect fit for your project?

In this guide, we’ll walk you through the key factors you should consider when selecting a multi-hole cable gland for your installation. By the end, you’ll be equipped with the knowledge to choose the right solution for your needs—one that’s secure, efficient, and built to last.

What Is a Multi-Hole Cable Gland?

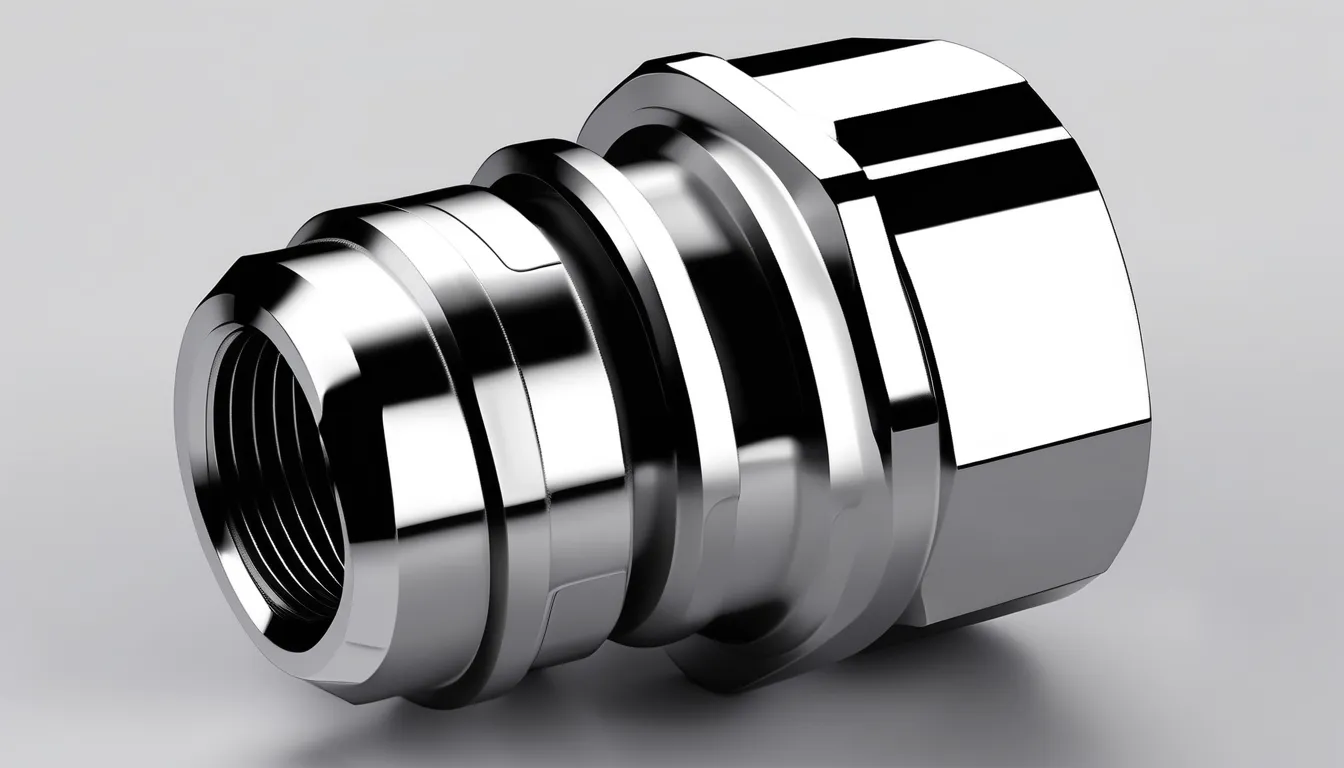

First things first: what exactly is a multi-hole cable gland? Simply put, a cable gland is a device used to secure and seal the end of an electrical cable as it passes through an enclosure, panel, or junction box. It protects both the cable and the enclosure from external elements, preventing the ingress of moisture, dust, and other contaminants.

A multi-hole cable gland goes one step further by accommodating multiple cables through a single entry point. This is especially useful in setups where several cables need to pass through a single gland, such as in control panels, distribution boxes, and industrial machinery. It simplifies the installation process, reduces clutter, and ensures the protection of multiple cables at once.

Why You Need to Choose the Right One

Choosing the right multi-hole cable gland is crucial for the overall performance and safety of your electrical system. The gland needs to:

- Provide a secure seal to prevent contamination.

- Accommodate cables of different sizes without compromising the integrity of the system.

- Ensure the system is vibration-resistant in environments where movement is common.

- Be suitable for the environmental conditions the cables will be exposed to (heat, moisture, chemicals, etc.).

Now, let’s dive into how you can make an informed decision when selecting the perfect multi-hole cable gland for your installation.

1. Determine the Number of Cable Entries You Need

One of the primary factors to consider when selecting a multi-hole cable gland is the number of cables you need to run through a single gland. Glands are available in a variety of configurations, from two-hole to six-hole models (or even more). The key is to select a gland that can comfortably accommodate all the cables you plan to use without overcrowding.

Think about your installation requirements:

- How many cables are going through the same enclosure?

- Are you using single-core or multi-core cables?

- Are the cables all the same size, or will you need to accommodate cables of different diameters?

The gland should offer a tight yet flexible fit for the cables while providing a secure seal. If you need to install a variety of cable sizes, look for glands with adjustable seals that can accommodate different cable diameters.

2. Consider the Material of the Cable Gland

The material of the gland is a critical factor in its ability to withstand the environment it’s placed in. There are several material options for multi-hole cable glands, each suited for different conditions:

- Brass: A popular choice for general-purpose installations. Brass cable glands are durable, corrosion-resistant, and well-suited for use in outdoor and industrial environments.

- Stainless Steel: If you need something more robust, particularly for harsh environments (e.g., marine, chemical plants), stainless steel glands offer superior corrosion resistance and strength.

- Plastic (Nylon or Polyamide): These lightweight glands are great for residential or light commercial applications. They offer UV resistance and good protection against moisture.

- Aluminum: For highly corrosive environments, such as chemical or offshore oil rigs, aluminum glands offer excellent resistance to harsh chemicals and salts.

Choosing the right material ensures the gland will be able to handle the environmental challenges it will face, whether it’s extreme temperatures, exposure to chemicals, or high humidity.

3. Check for Sealing and Protection Features

The sealing ability of a cable gland is what keeps your electrical system safe from external elements. Look for multi-hole cable glands that have high-quality sealing mechanisms to keep moisture, dirt, dust, and chemicals from entering your enclosures.

Look for the following sealing features:

- IP Rating (Ingress Protection): An IP rating tells you how resistant the gland is to dust, dirt, and water. For example, an IP68 rating means the gland is dust-tight and can withstand immersion in water. If your installation is exposed to moisture (such as outdoor use, marine environments, or chemical plants), an IP66 or IP68 rating will ensure robust protection.

- Elastic or Rubber Seals: These seals adapt to the size and shape of the cable, offering a flexible but tight seal to prevent ingress.

Be sure to choose a gland that offers adequate protection based on the environmental conditions and the sensitivity of the electrical system it’s serving.

4. Vibration Resistance and Mechanical Strength

In industries such as automotive, aerospace, and manufacturing, machinery vibrations are a constant. If your cables are in environments where there’s significant movement or mechanical stress, vibration resistance is a key consideration.

Look for multi-hole cable glands that feature:

- Locknuts: These provide an extra layer of stability and prevent the gland from loosening due to vibrations.

- Rubber Seals: A rubber seal will absorb vibrations and help keep the multi cable gland s in place without compromising the gland’s effectiveness.

For industrial or high-performance applications, choosing a vibration-resistant gland will prevent wear and tear on your cables, extending their life and reducing maintenance needs.

5. Temperature Resistance

Electrical systems are often exposed to temperature fluctuations, ranging from extreme heat to freezing cold. Make sure the multi-hole cable gland you choose is rated to withstand the temperature range it will be exposed to.

For outdoor or industrial applications, choose glands that can handle both high and low temperatures without deforming or losing their sealing capabilities. Materials such as stainless steel or nylon often have a broader temperature tolerance, making them suitable for harsh environments.

6. Ease of Installation and Maintenance

The best multi-hole cable glands are those that are easy to install and maintain. Installation should be straightforward, with no special tools required. Look for glands that allow for quick and secure assembly, especially if you’re working on a large-scale project with numerous cable entries.

Some glands also feature removable components, which make maintenance or upgrading easier. Being able to swap out a damaged seal or replace an insert without disassembling the entire system saves time and effort.

7. Compliance with Industry Standards

Finally, ensure that the multi-hole cable gland you choose complies with relevant industry standards. For example, if you’re working in hazardous environments (oil rigs, chemical plants, etc.), look for glands that are ATEX-certified or have IECEx approvals for use in explosive atmospheres. These certifications ensure that the glands meet strict safety standards and are designed to prevent sparks or other electrical hazards.

Conclusion: Choosing the Perfect Multi-Hole Cable Gland

Selecting the right multi-hole cable gland for your installation is crucial for maintaining the integrity, safety, and longevity of your electrical system. By considering the number of cable entries, material durability, sealing and protection features, vibration resistance, and compliance with industry standards, you can make an informed decision that suits your specific needs.

Whether you’re working on a residential, commercial, or industrial project, the right multi-hole cable gland will ensure a secure, safe, and efficient cable management solution. Take the time to carefully assess your installation requirements, and choose a gland that’s up to the task!